Flame - Retardant Casting Epoxy Resin for Transformer Coil Encapsulation - Enhanced Safety

Safety is a top priority in any electrical application, and our flame - retardant casting epoxy resin for transformer coil encapsulation offers enhanced safety features.

This epoxy resin is formulated with flame - retardant additives that prevent or slow down the spread of fire. In the event of an electrical fault or overheating in the transformer, the risk of a fire breaking out is always present. Our flame - retardant epoxy resin acts as a fire - resistant barrier, reducing the likelihood of a fire spreading and causing further damage.

When exposed to high temperatures, the resin does not easily catch fire. Instead, it forms a charred layer that acts as an additional protective shield, further inhibiting the combustion process. This property is especially important in industrial and commercial settings where transformers are used, as it helps to protect the surrounding environment and equipment from potential fire hazards.

Despite its flame - retardant properties, the resin still provides excellent electrical insulation. It ensures that the transformer coils operate safely and without electrical malfunctions. It also has good mechanical properties, allowing it to withstand the normal stresses and vibrations in transformer operations. With our flame - retardant casting epoxy resin, transformer coil encapsulation not only protects the coils but also contributes to overall fire safety in electrical systems.

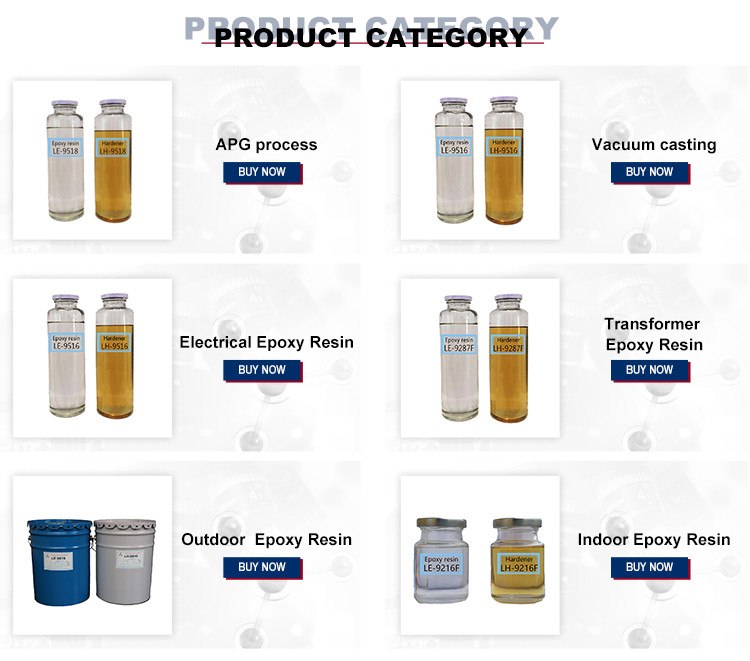

Brief Introduction

LE-9215 is a modified BPA (bisphenol A) epoxy resin, combined with LH-9215, a liquid modified carboxylic anhydride hardener. This thermally conductive epoxy adhesive is designed to protect electrical power components while providing effective insulation.

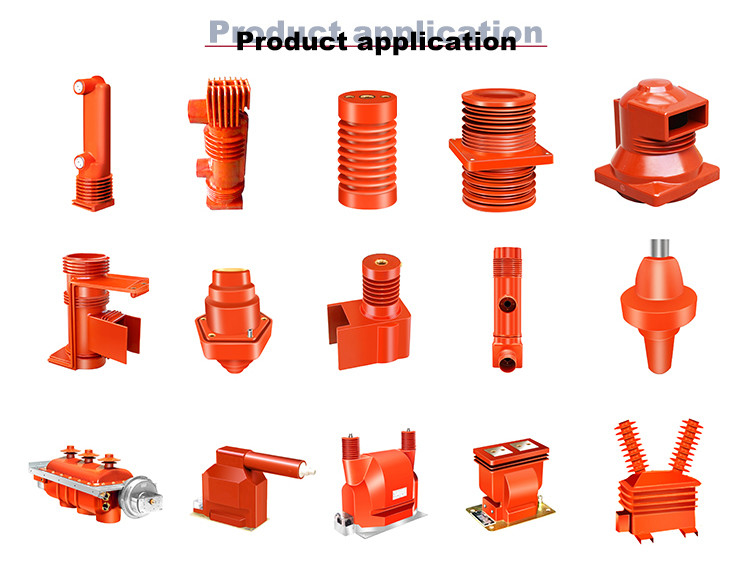

Applications

This epoxy resin is suitable for medium and high voltage electrical insulators, including contact boxes rated for 12kV to 40.5kV, insulators, and other related products.

Processing Methods

The material can be processed using a conventional gravity casting method under vacuum or through an Automatic Pressure Gelation (APG) process. The production methods can be customized to fit the client’s existing manufacturing techniques.

Properties

LE-9215 exhibits excellent resistance to thermal shock, along with superior mechanical and dielectric properties, making it an ideal choice for demanding electrical applications.

Formulation

| Epoxy resin |

LE-9215 |

100 pbw |

| Hardener |

LH-9215 |

100 pbw |

| Filler |

Silica powder |

300-400 pbw |

| Color paste |

LC series * |

3 pbw |

Advantage

Package Image

Shipment image

Example application image

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!